Ekide, more than 30 years of history.

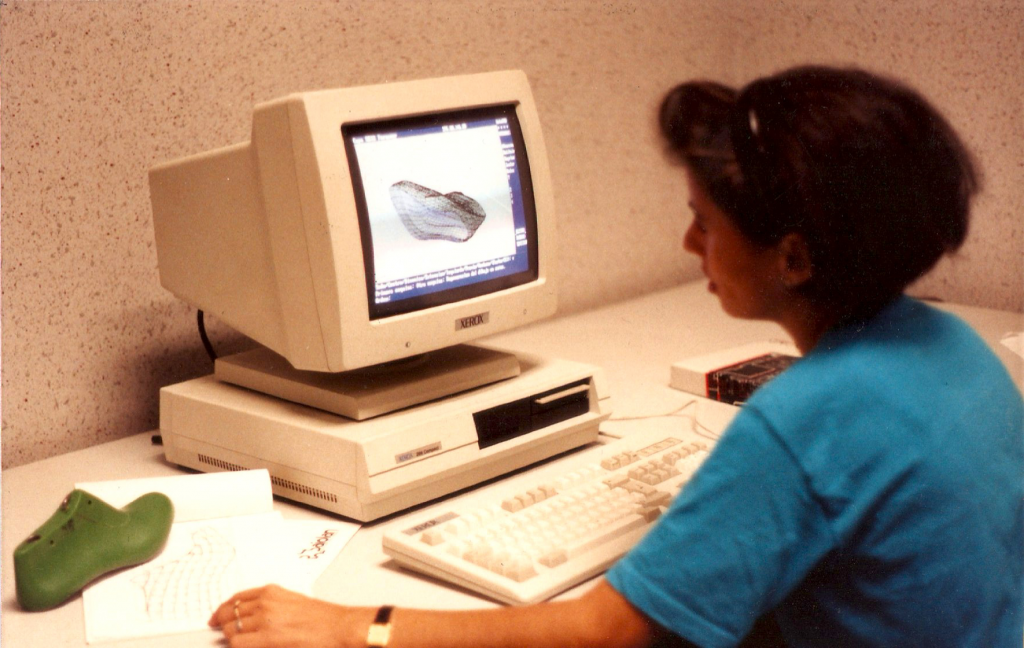

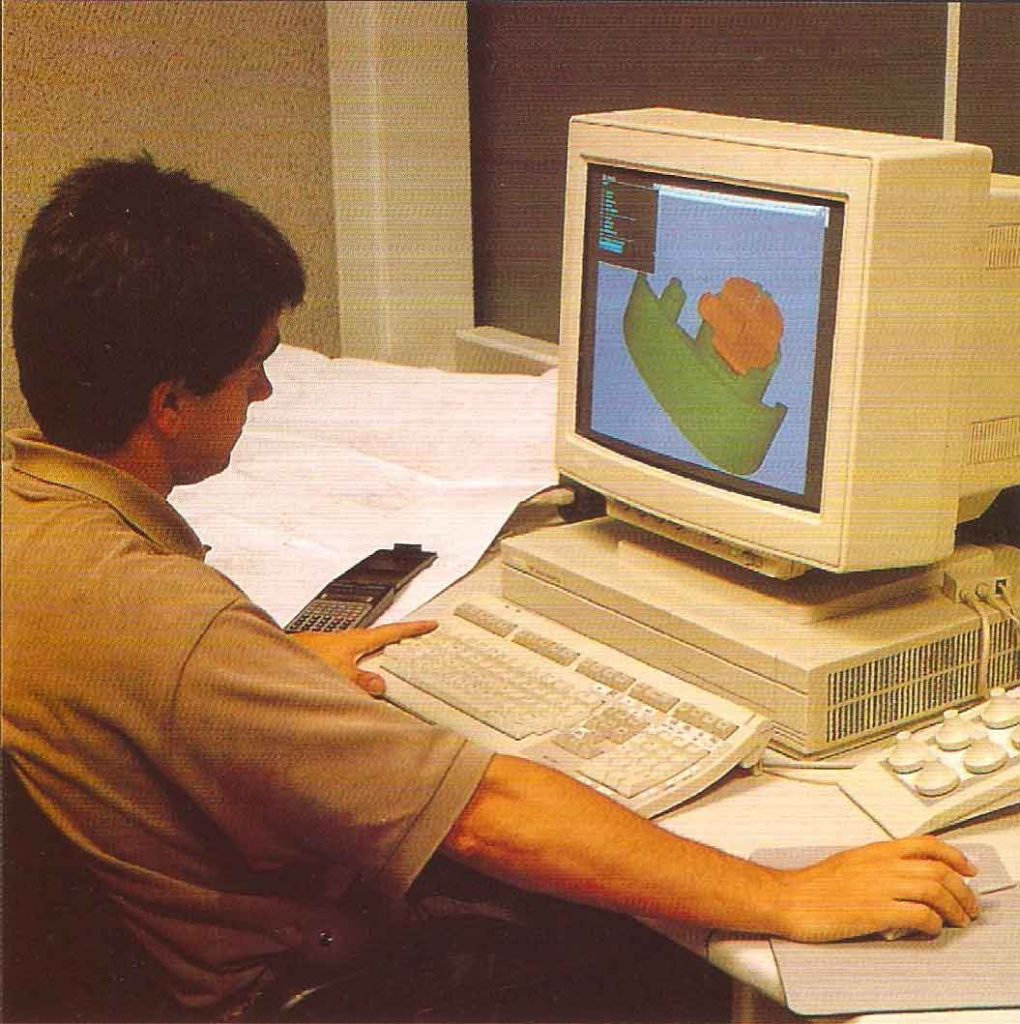

The 30 year history of Ekide is a reflection of the business effort, work and vision,making the most of each opportunity.

This project began with three employees and today, 30 years later, Ekide is a well established company with over 100 employees, partnering with strategic and leading companies in the engineering sector as well as the development and manufacturing of new products. Ekide is proud to have made the best of each and every opportunity they have encountered throughout these years on their journey to success. Ekide continues looking forward, working, improving and applying the latest technologies, with the same optimism and energy that motivated those three entrepreneurs to start the company.