We manufacture high-added-value assemblies, integrating components in multiple materials through a range of advanced technologies.

Extensive knowledge in multi-material processes

Our extensive knowledge of engineering and manufacturing allows us to offer high-value components in different materials, using the most advanced production processes.

Years of experience in the field allow us to develop highly complex assemblies.

– Automated warehouse

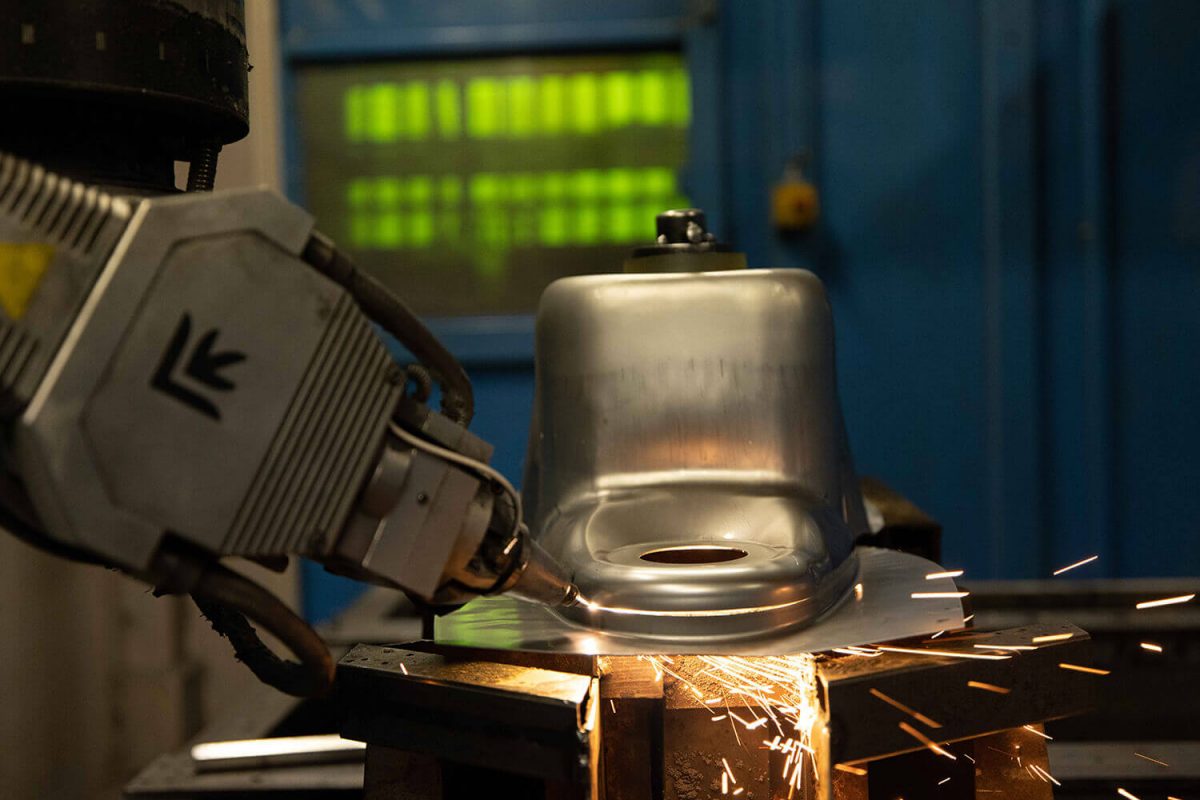

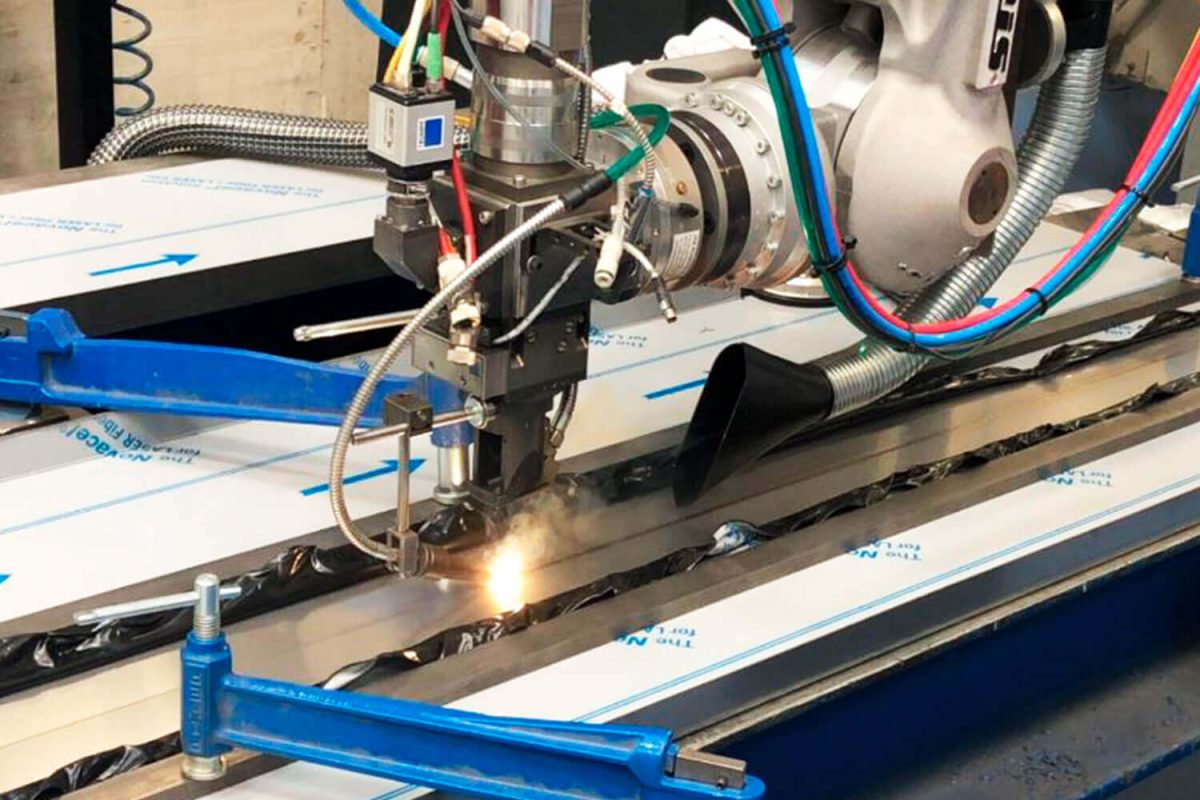

– 2D laser cutting

– 3D laser cutting

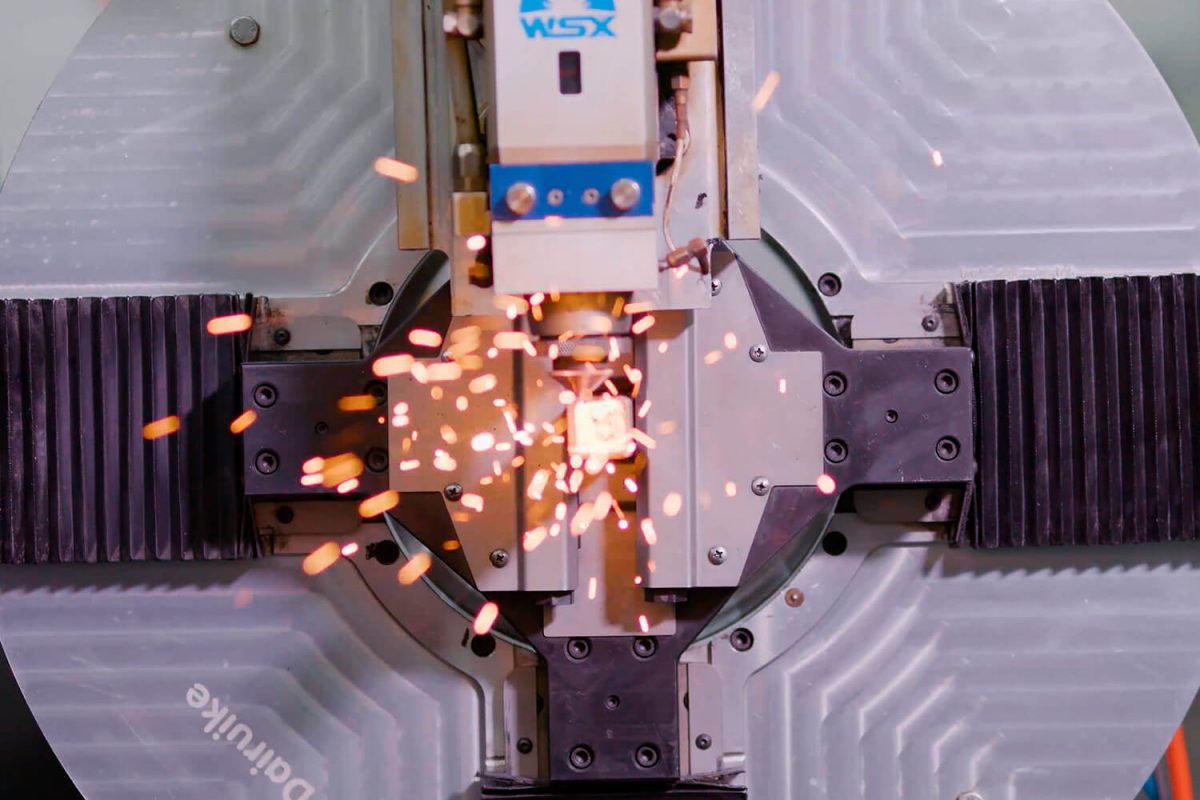

– Laser tube cutting

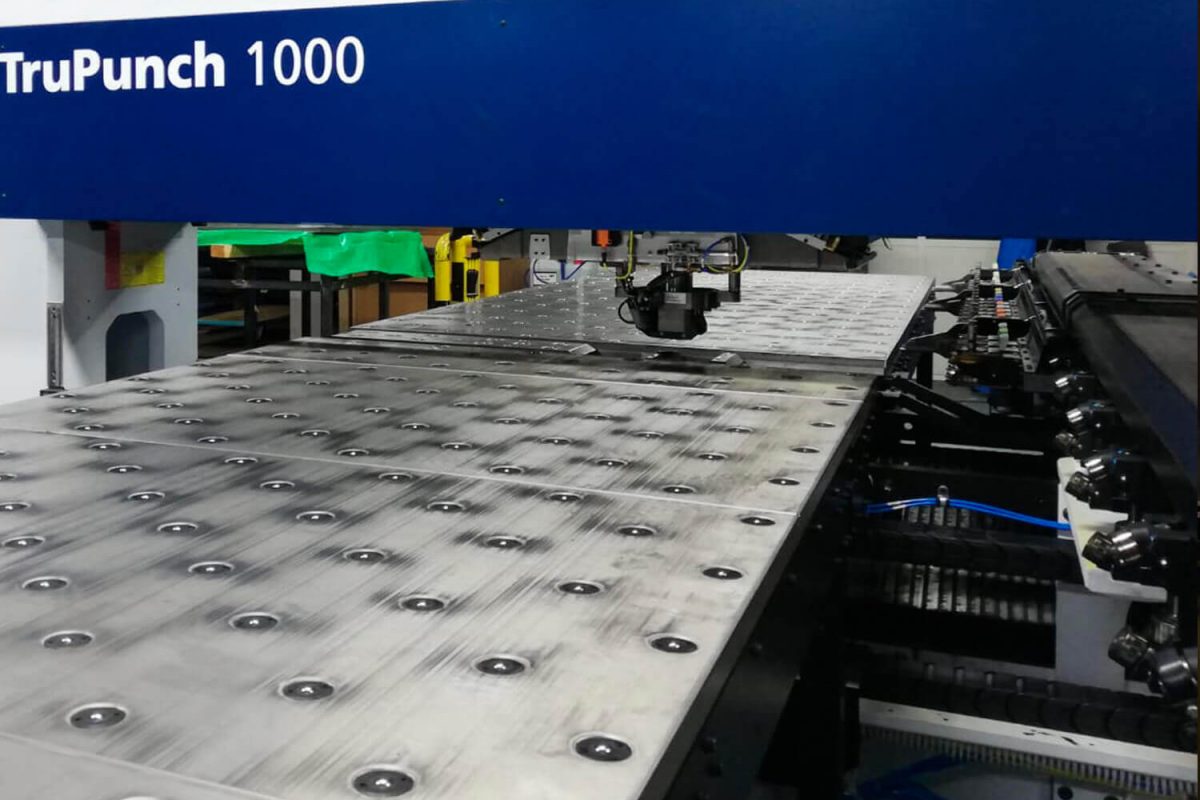

– Punching machines

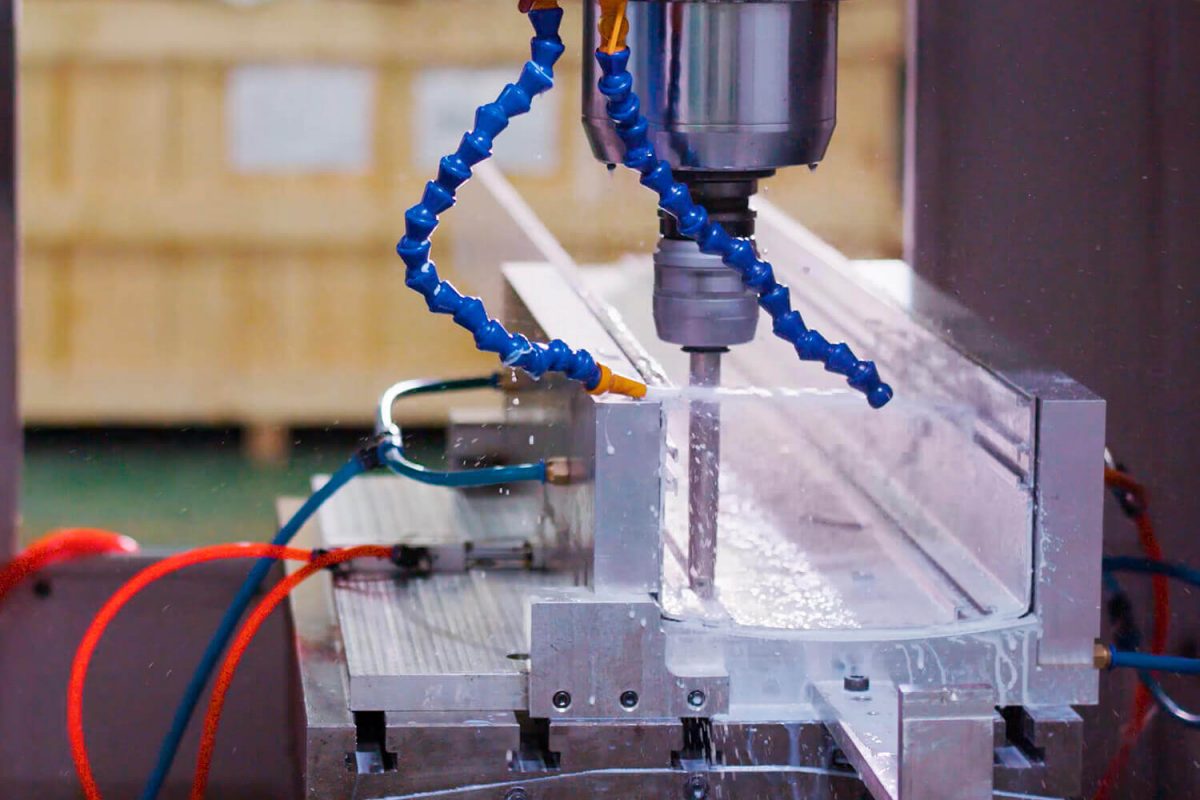

– M3-axis CNC machining

– 5-axis CNC machining

– Welding equipment

– Tube Bending

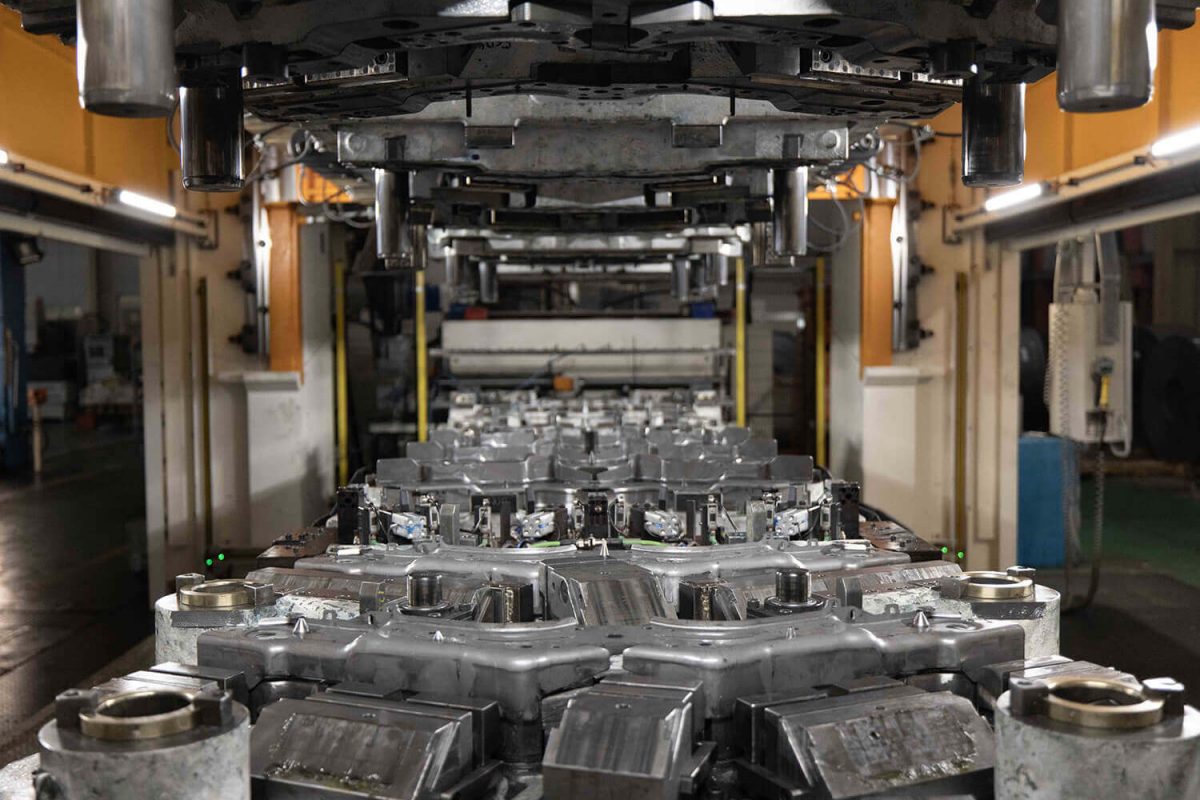

– Stamping

– Deep drawing

– Deburrer

We manufacture components in advanced composite materials, with unbeatable weight-stiffness ratios for highly demanding projects.

– Manual lamination

– SMC

– Pre-preg (Autoclave)

– Vacuum infusion

EKIPANEL

In addition, our extensive know-how in the field has allowed us to create our own product: Ekipanel, a sandwich panel for floors, for sectors such as rail, nautical or the bus sector.

We have extensive experience in the injection of thermoplastic parts when manufacturing prototypes and short series.

– Plastic Injection

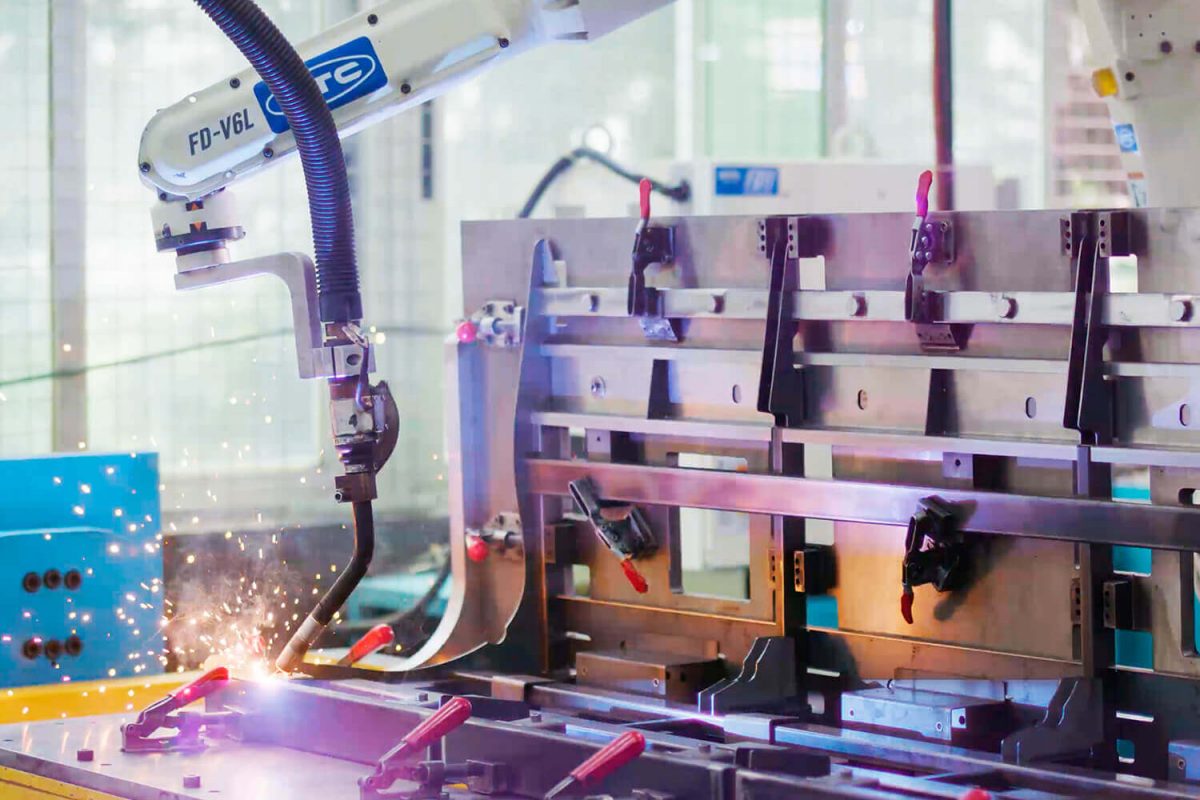

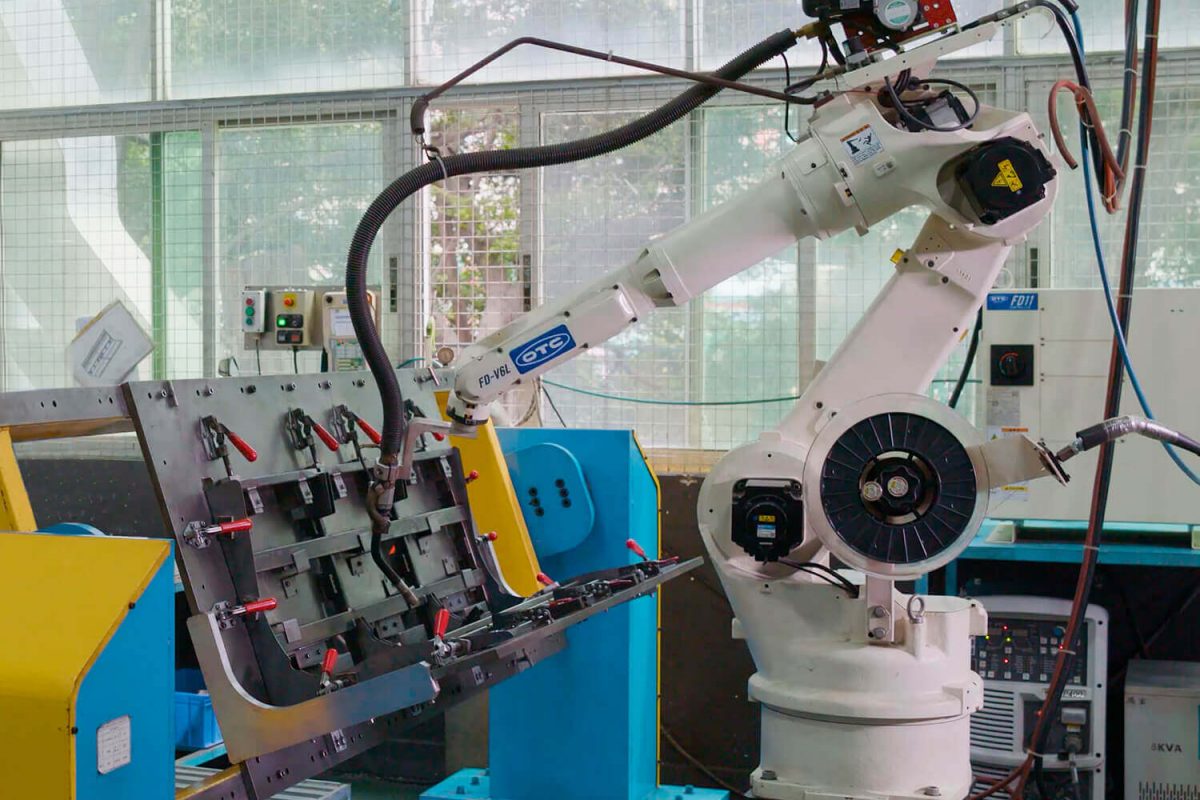

Joining technologies, maximum quality and durability

We pay special attention to joining technologies, processes that meet demanding certificates, providing the highest quality and durability to the sets developed.

– Bonding (DIN 6701 A2 & DIN 2307)

– Welding robots (EN 15085 CL1)

– Manual welding (Aluminum and Stainless Steel)

– Friction welding (SFW)

– Laser welding

– Ultrasound test

– Penetrant liquid analysis

– Magnetic particle analysis

– Macrography

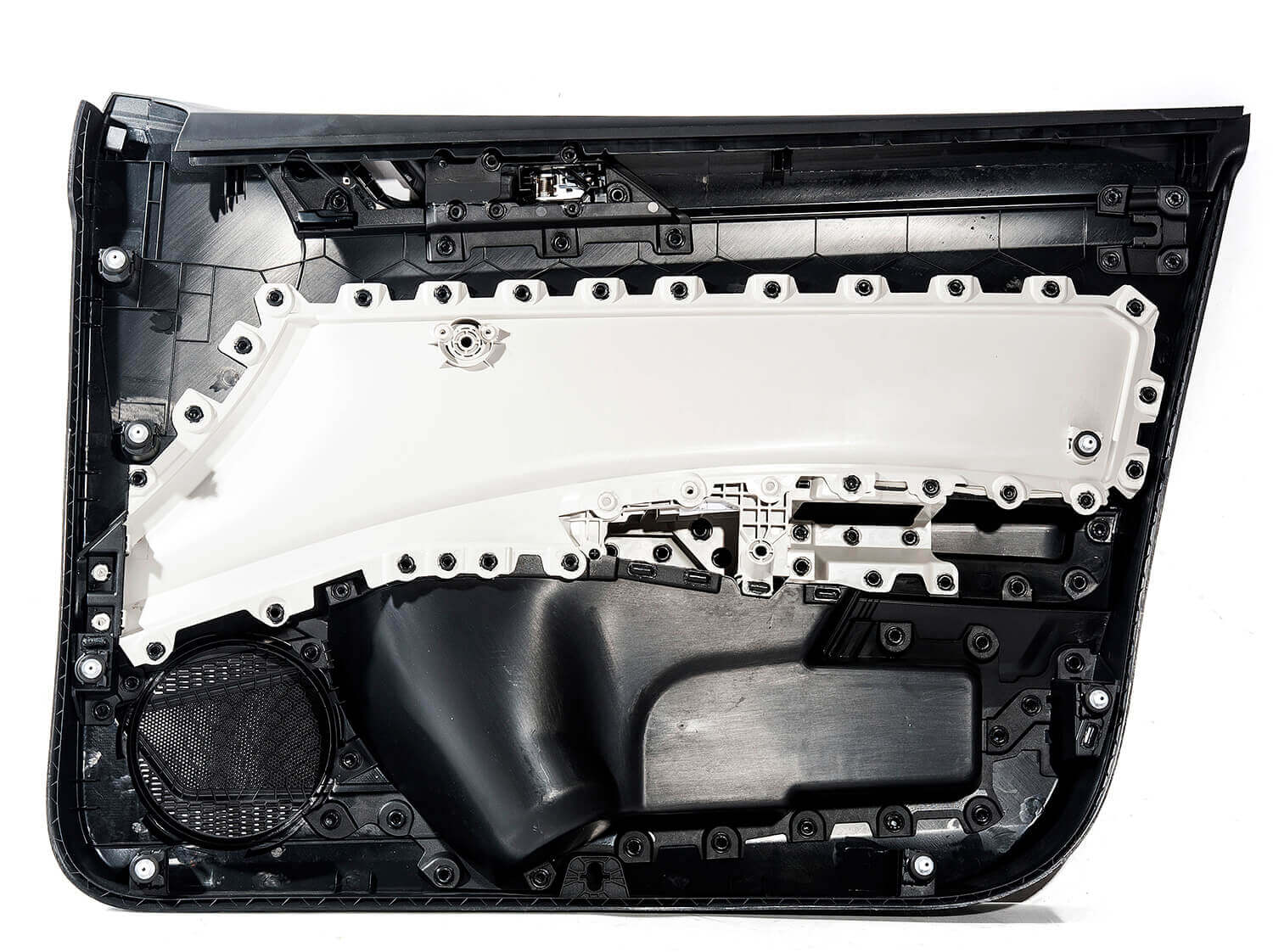

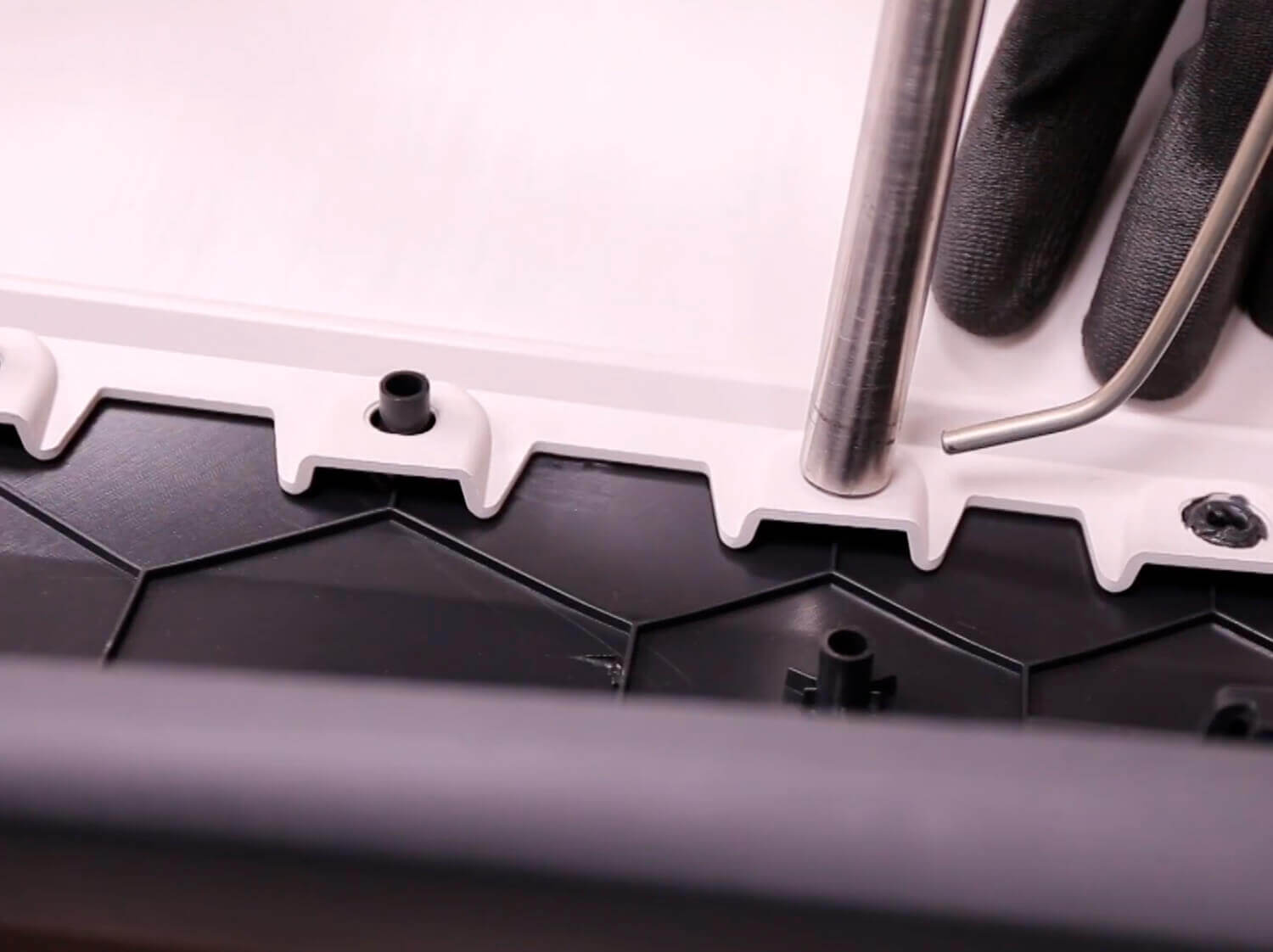

Complex assemblies

We have optimized facilities for assembling complex assemblies, according to customer specifications, with a high level of efficiency.

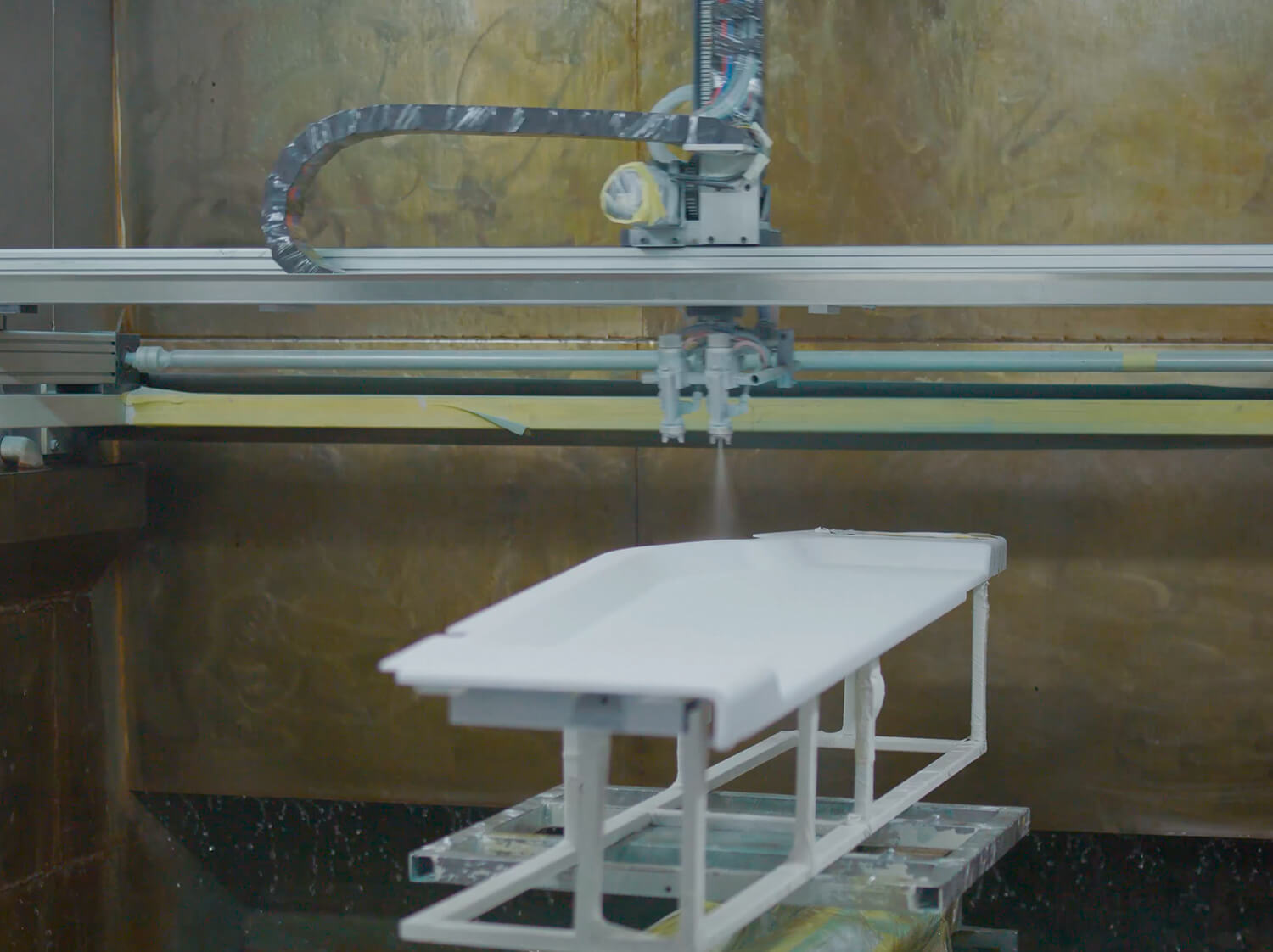

Demanding finishes: top-quality final product

We close the manufacturing process by integrating finishes of the highest quality, so that the final product meets the needs required by our customers in terms of appearance, texture and final behavior for which they have been designed.

– Wet painting facilities

– Robot wet painting

– Powder painting

– Polishing

– Screen printing

– Laser engraving

– Chrome plated

Other finishes are subcontracted to nearby and approved suppliers (KTL, anodized, passivated, galvanized, zinc plated, etc.).

Testing: compliance with stringent regulations

We carry out the necessary tests on our products, which provides us with the highest quality and safety, and compliance with demanding regulations. To do this, we collaborate with a network of trusted multidisciplinary laboratories. Accredited laboratories according to current national and international standards.